SHM, with 40 years of know-how, offers tailored converting machines to satisfy the various demands of customers in the flexible packaging industry.

05

OTHER CONVERTING MACHINE LINE

Enhanced Material Processing Efficiency

Precision Cutting and Slitting Capabilities

Reduction in Material Waste

Flexibility in Handling Various Material Types and Sizes

Mechanical Speed

Product Width

Unwinder Diameter

Rewinder Diameter

Min. Slit Width

Unwinder Chucking Type

Core

Up to 500 m/min

Up to 1700 mm

800 mm / 1000 mm

400~500 mm

50 mm Upwards

Shaft / Shaftless

3”, 6”

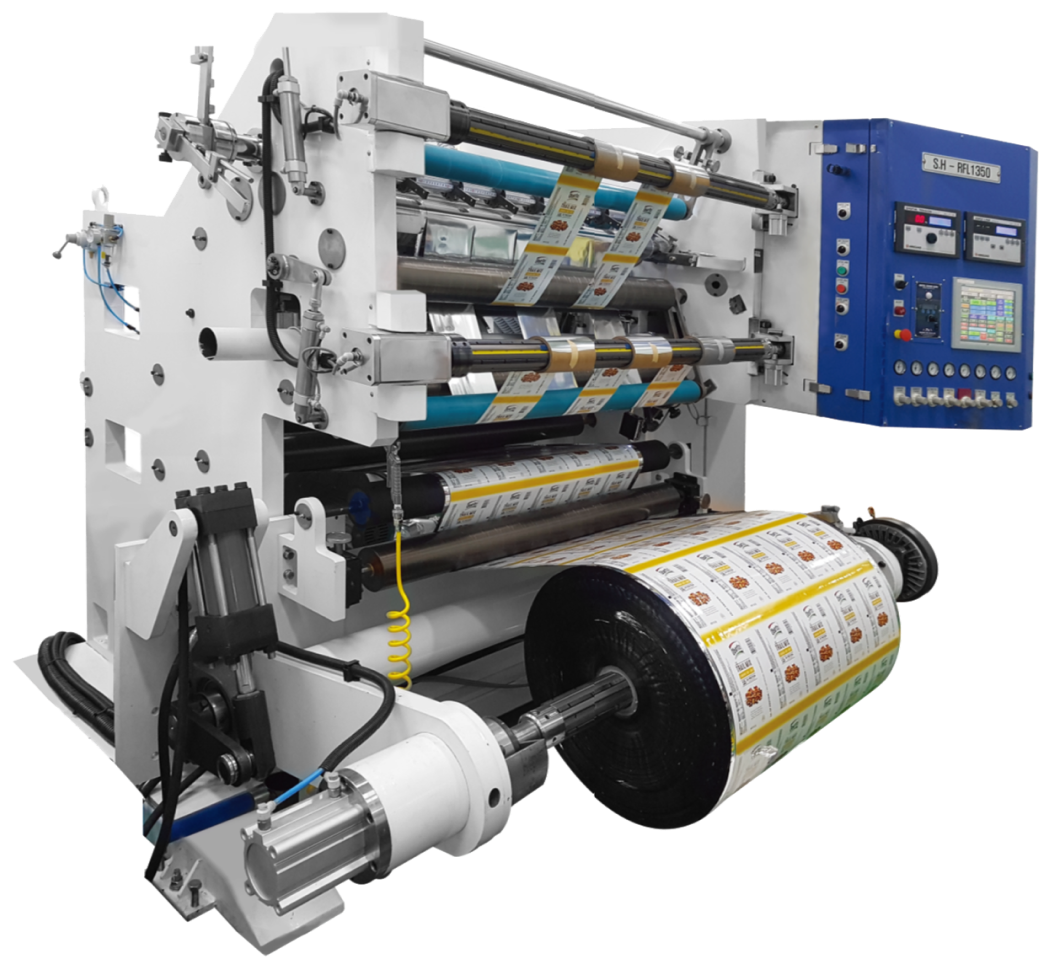

SLITTER

This is a machine for cutting various types of flexible packaging materials and printing materials. Through SHM's winding mechanism, stable tension control during winding is possible, ensuring consistent processing quality at a slitting speed of up to 500m/min.

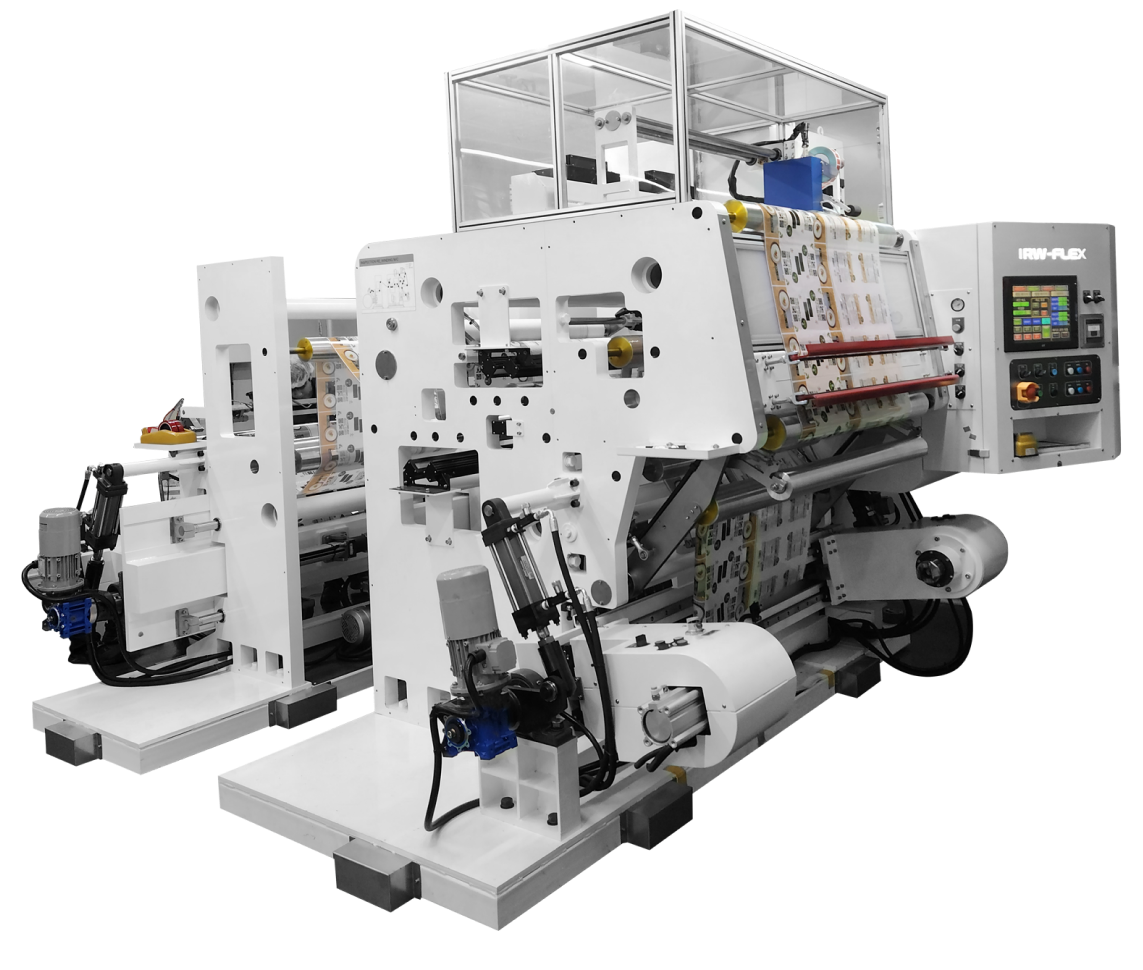

Designed to use state-of-the-art cameras and high-performance image processing software to meticulously inspect the quality of printed products and detect even the slightest defects.

Automated inspection systems enhance packaging line efficiency by performing tasks much faster and more accurately than manual inspections.

Provide a standalone operator panel equipped with HMI.

Mechanical Speed

Product Width

Winder Diameter

Unwinder Chucking Type

Core

Up to 500 m/min

Up to 1700 mm

800 mm / 1000 mm

Shaftless

3”, 6”

INSPECTION

It is a machine that uses cameras and image processing software to inspect the quality of printed products, detect foreign substances, and filter out defective items. It plays a crucial role in enhancing the efficiency of the packaging line and strengthening quality control, ensuring that safe and high-quality products are delivered to the end consumer.

Enhanced Material Processing Efficiency

Reduction in Material Waste

Flexibility in Handling Various Material Types and Sizes

Mechanical Speed

Product Width

Winder Diameter

Unwinder Chucking Type

Core

Up to 150 m/min

Up to 1700 mm

Up to 1000 mm

Shaft / Shaftless

3”, 6”

HOTMELT COATING

This machine heats solid hot melt adhesive to a liquid state and uniformly applies it to the surface of packaging materials, then quickly cools it to form a coating. After cooling, it immediately exhibits strong adhesive strength, allowing for rapid packaging processes. Additionally, it is environmentally friendly as it does not use solvents.