Explore SHM's innovative laminating line for diverse material processing.

Introducing DUAL-LAMIFLEX with versatile, interchangeable coating heads!

02

LAMINATING LINE

SL-LAMIFLEX

Introducing SHM's “High-Level"

SL-LAMIFLEX solution, a machine designed for producing 2-layer laminates using solvent-free adhesives. It offers environmental friendly higher efficiency and productivity compared to solvent-based laminating.

Mechanical Speed

Product Width

Roll Diameter

Film Structure

Up to 500 m/min

Up to 1700 mm

Up to 1200 mm

2 layers

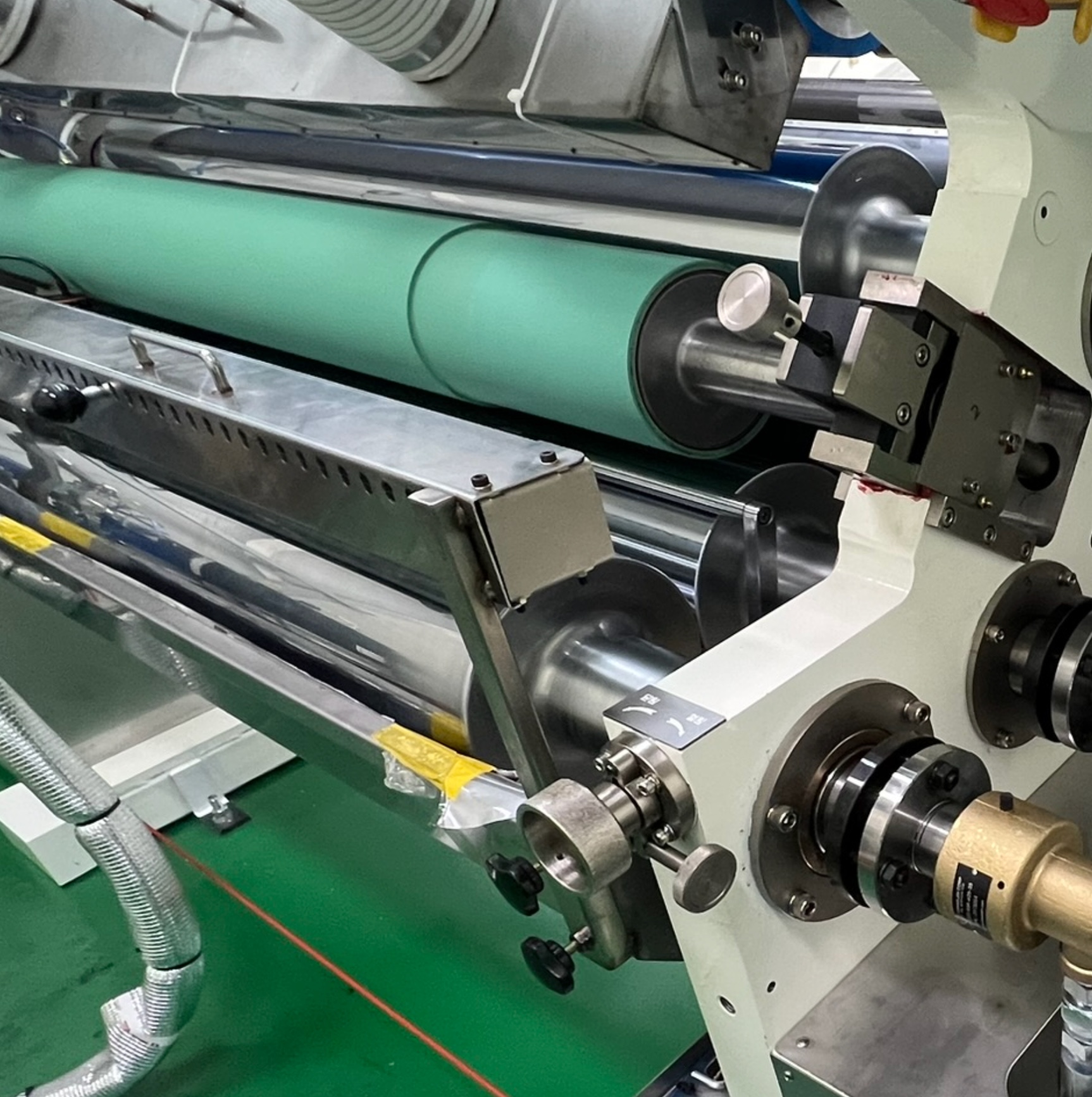

SL(Solventless) Coating

System Composition: 5-roller system

Technological Features: SHM specialized roller manufacturing technology, hot water circulation device

Effects: Reduced temperature variations, maintained high production speeds, consistent adhesive quality

Convenience: Sleeve-type transfer roller, easy roller replacement

DRY-LAMIFLEX

The “High-Level" DRY-LAMIFLEX solution from SHM is for solvent/water-based adhesive lamination with a gravure coating roll. It offers high precision and consistency in coating weight, allowing for the production of advanced products such as retort, sterilized, and medical pouches.

Mechanical Speed

Product Width

Roll Diameter

Film Structure

Up to 300 m/min

Up to 1700 mm

Up to 1200 mm

2 layers

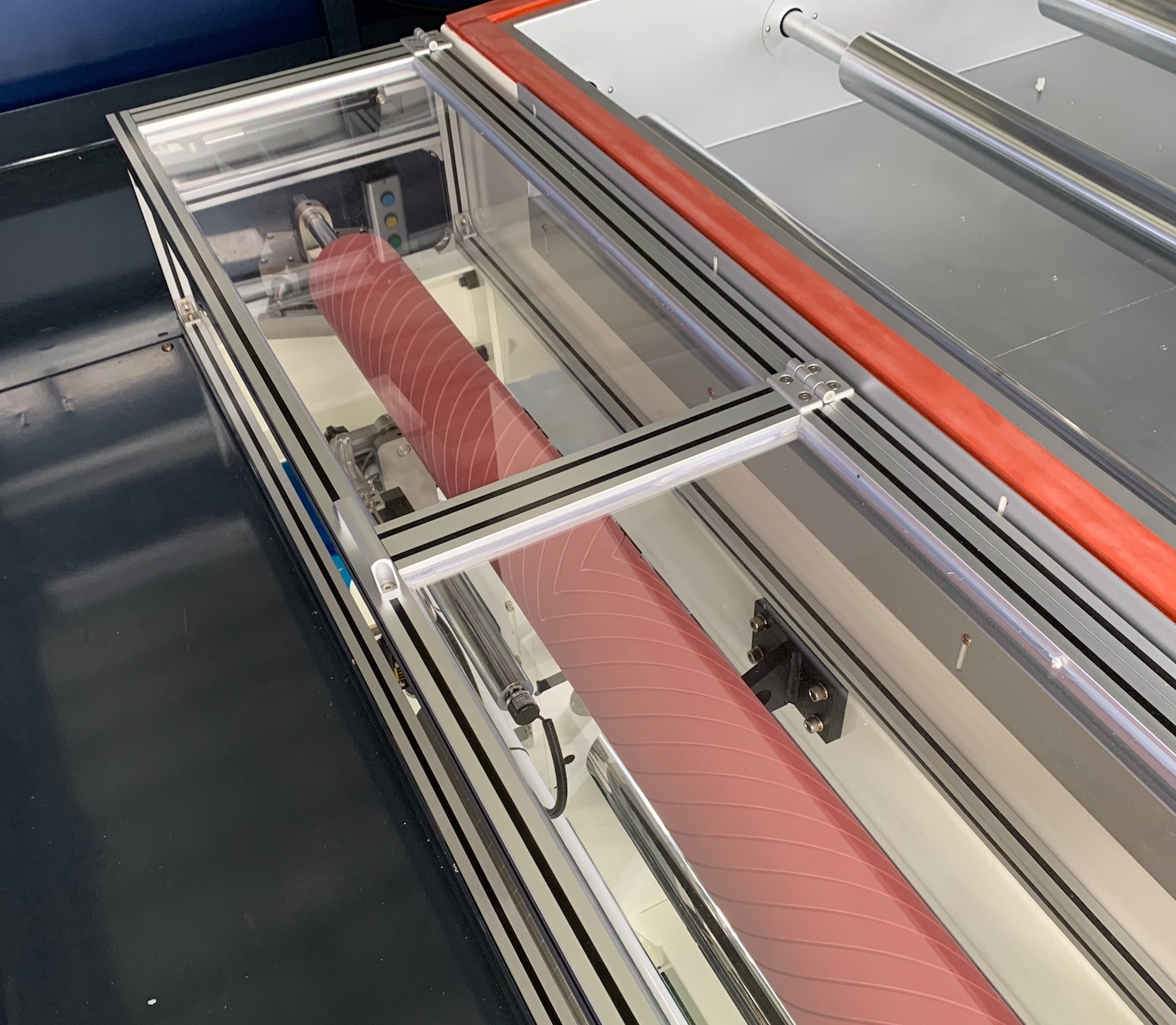

DRY(Gravure) Coating

DRY(Gravure) Coating Roll and Flexible Doctor Blade System: high precision and consistency in coating weight even at high speeds.

Speed-Synchronized Smoothing Roll: to uniform adhesive application on the substrate.

Easy cleaning and maintenance: Teflon coated Stainless steel cover for coating area

DRY Chamber

High efficiency, high-temperature low-pressure operation, and long lifespan with Versatile Heating Solutions , Thermal oil, steam, electric, gas burner.

Easy access to the detachable nozzles and internal rollers, facilitating cleaning and maintenance by Motor-driven Vertical Opening and Closing Design

Energy-Saving Capabilities, E-SAVER(Optional) reduce carbon emissions and production costs

Winder

Dancer roll type Precise Tension Control

Air shaft/ Shaftless chucking for quick change

Linear movement type Auto splicer for unwinder

Near roll : automatically keep the gap between the winding web roll

Laminating

Precision 3-Roll Lamination System Steel heating / Rubber / Back-up roll

Heating and Cooling Circulation Systems

Customized / Option

Flexible component-based design for customized cost effective user layouts

User-friendly modular configuration system

Coating Weight Measurement, corona treatment, quality inspection, and more

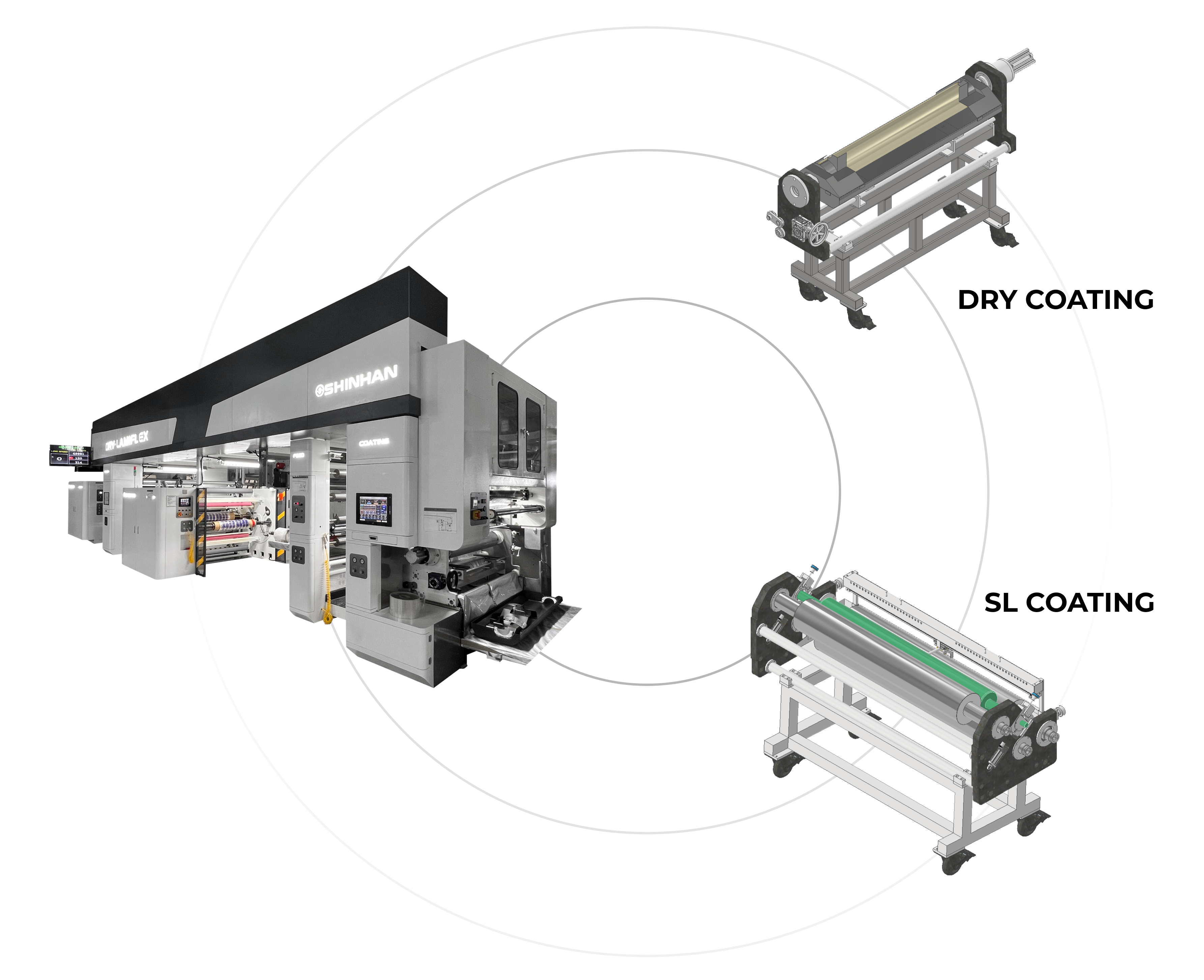

DUAL-LAMIFLEX, “TWO-IN-ONE” MACHINE. EASY, FAST COATING TECHNOLOGY CHANGE OVER. DUAL-LAMIFLEX, “TWO-IN-ONE” MACHINE. EASY, FAST COATING TECHNOLOGY CHANGE OVER. DUAL-LAMIFLEX, “TWO-IN-ONE” MACHINE. EASY, FAST COATING TECHNOLOGY CHANGE OVER. DUAL-LAMIFLEX, “TWO-IN-ONE” MACHINE. EASY, FAST COATING TECHNOLOGY CHANGE OVER. DUAL-LAMIFLEX, “TWO-IN-ONE” MACHINE. EASY, FAST COATING TECHNOLOGY CHANGE OVER. DUAL-LAMIFLEX, “TWO-IN-ONE” MACHINE. EASY, FAST COATING TECHNOLOGY CHANGE OVER. DUAL-LAMIFLEX, “TWO-IN-ONE” MACHINE. EASY, FAST COATING TECHNOLOGY CHANGE OVER. DUAL-LAMIFLEX, “TWO-IN-ONE” MACHINE. EASY, FAST COATING TECHNOLOGY CHANGE OVER. DUAL-LAMIFLEX, “TWO-IN-ONE” MACHINE. EASY, FAST COATING TECHNOLOGY CHANGE OVER. DUAL-LAMIFLEX, “TWO-IN-ONE” MACHINE. EASY, FAST COATING TECHNOLOGY CHANGE OVER. DUAL-LAMIFLEX, “TWO-IN-ONE” MACHINE. EASY, FAST COATING TECHNOLOGY CHANGE OVER

Mechanical Speed

Product Width

Roll Diameter

Heating system

Up to 500 m/min

Up to 1700 mm

Up to 1200 mm

Thermal oil, steam, electric, gas burner

Substrates

Adhesives

Film, laminates, paper, aluminum

Solvent-based, water-based, solventless

Dry(Gravure)

Solventless

Solvent-based, water-based

Solventless