SHM, a leader in extrusion coating and laminating, provides customized solutions

01

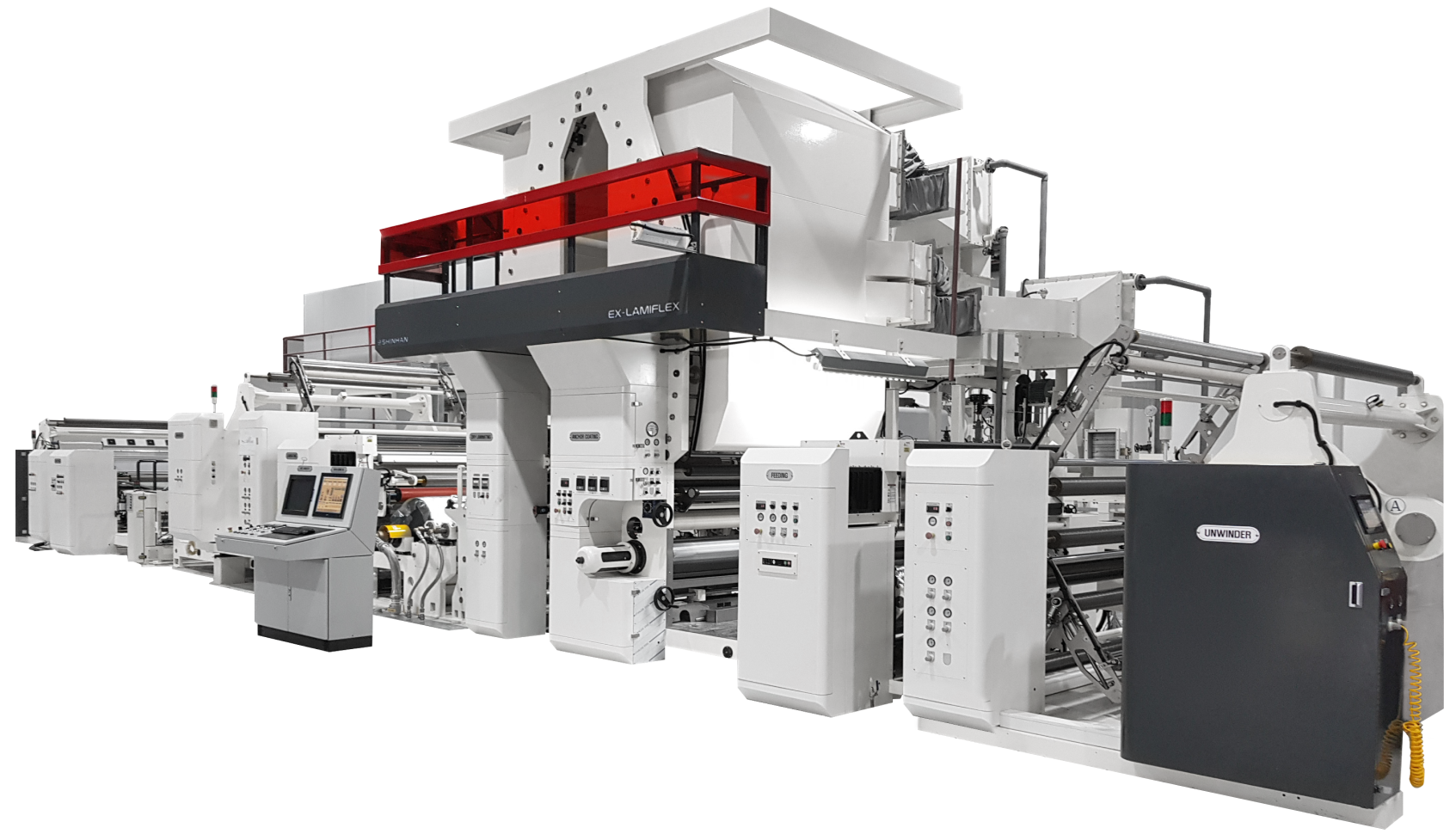

EXTRUSION COATING AND LAMINATING LINE

EX-LAMIFLEX

Introducing SHM's "Entry-Level"

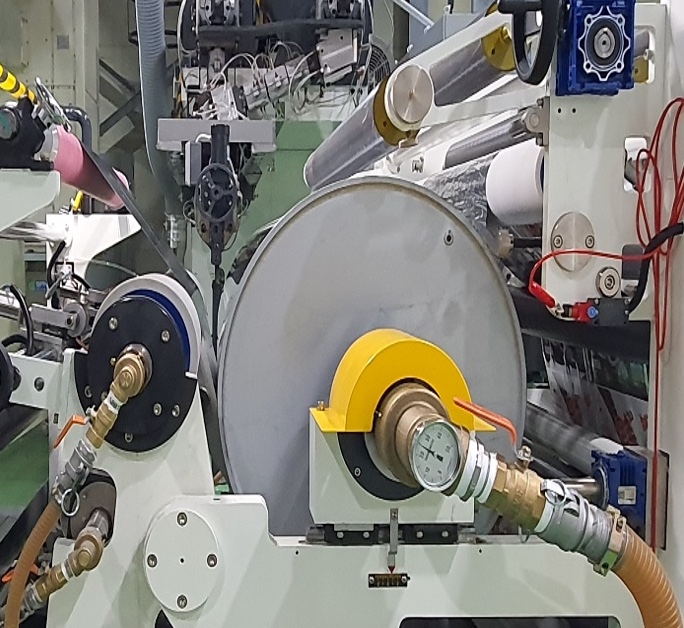

EX-LAMIFLEX solution. This laminating machine utilizes a SIngle extrusion unit to produce 2-4 layer packaging materials.

Mechanical Speed

Product Width

Roll Diameter

Film Structure

Up to 400 m/min

Up to 1700 mm

Up to 1500 mm

2~4 layers

TANDEM-LAMIFLEX

Mechanical Speed

Product Width

Roll Diameter

Film Structure

Up to 400 m/min

Up to 1700 mm

Up to 1500 mm

2~7 layers

Introducing SHM's "High-Level"

TANDEM-EX-LAMIFLEX solution. This laminating machine utilizes Tandem extrusion unit to produce 2 to 7-layer packaging materials.

EXTRUSION COATING AND LAMINATING LINE

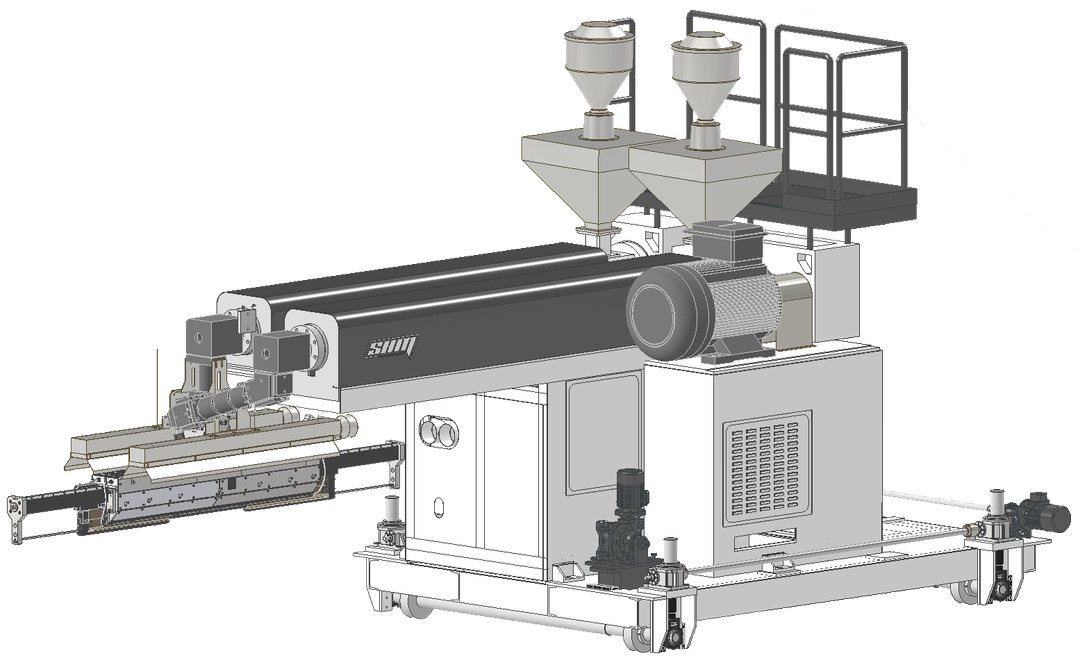

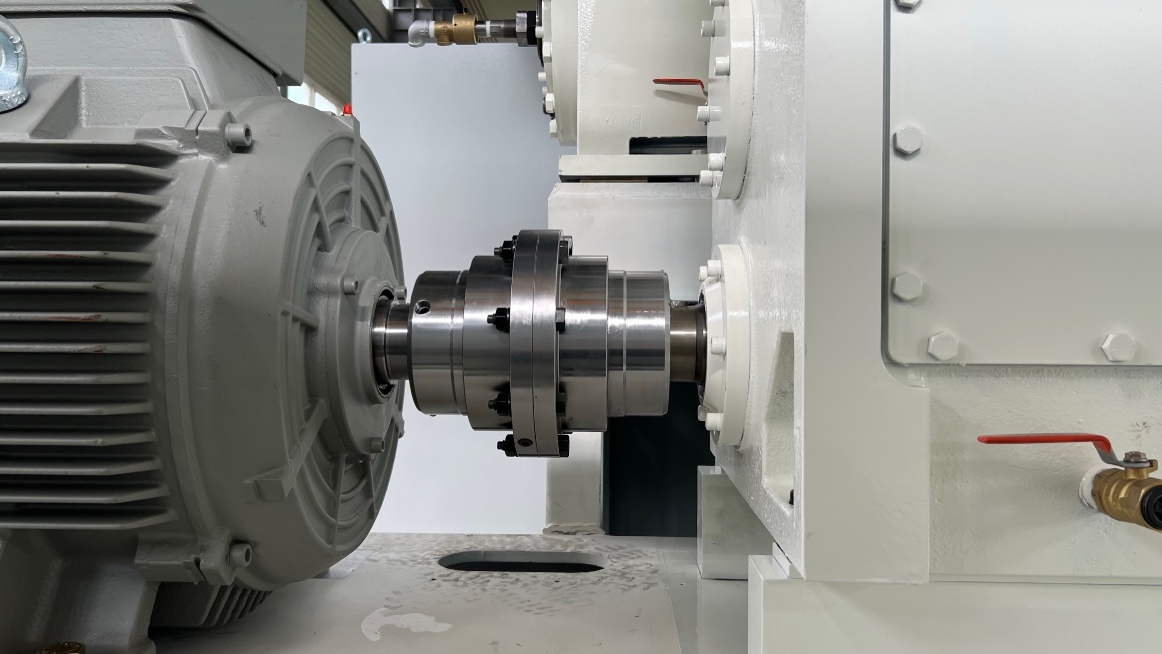

Extrusion Unit

SHM's extruders feature extensive die position adjustments through the movement of the carriage, allowing for optimal control of extrusion parameters. We offer various extruder layout configurations for different extruder sizes, screen changers, and dies. All electrical equipment and temperature control (inverter control) panels related to the extruder are located on the board to minimize floor space requirements and reduce cable connections from the machine to the extruder.

Screw design that delivers optimal mixing performance

Precise temperature control and energy efficiency

Easy air gap adjustment

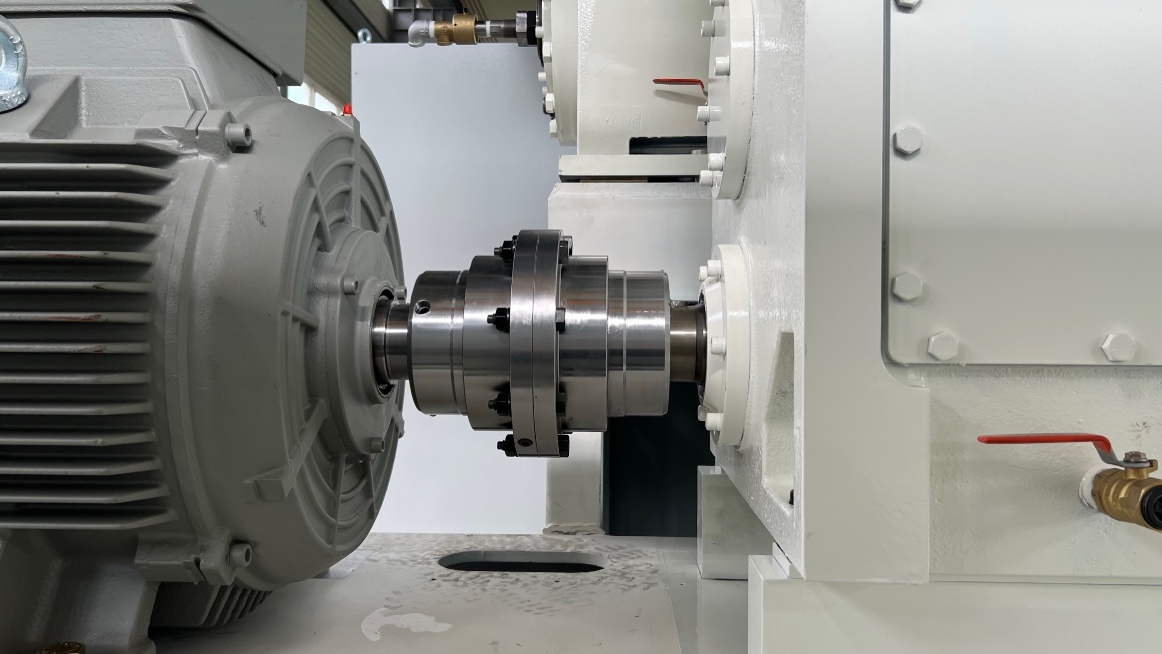

Durable gearbox

Mechanical Speed

T-die Width

Screw & Barrel

Air Gap

Up to 400 m/min

Up to 1800 mm

Up to Ø120 mm

Control of up and down by motor

Substrates

Resin

Film, Laminates, Paper, Aluminum

PE, PP, Acid Copolymers

Flexible Packages

Plastic Films ,Paper, Al-foil

Snack foods, condiment packs, food

dry goods, toothpaste tubes, coffee

packages, cosmetic packages,

Medicine packages, pet food

Paper

FoodPackages, Cup Stock

SHM's extruders feature extensive die position adjustments through the movement of the carriage, allowing for optimal control of extrusion parameters. We offer various extruder layout configurations for different extruder sizes, screen changers, and dies. All electrical equipment and temperature control (inverter control) panels related to the extruder are located on the board to minimize floor space requirements and reduce cable connections from the machine to the extruder.

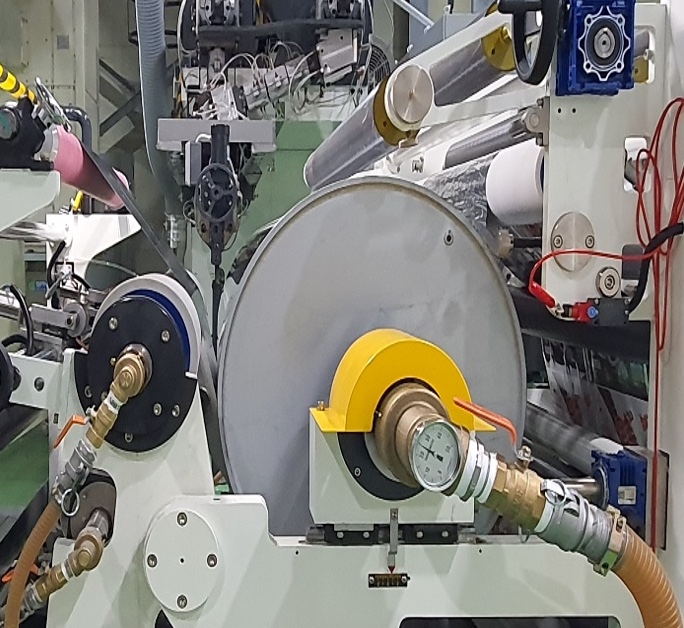

Extrusion Laminating Unit

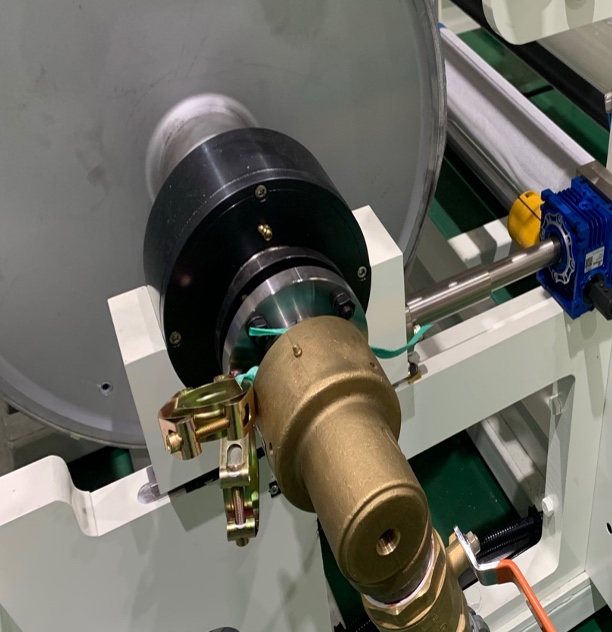

The lamination configuration of a 3-rolls system, which applies cooling and pressure, is the most critical system in the machine. With highly precise engineering, the rolls ensure consistent temperature and pressure across the entire web, preventing stress on the coated materials and enhancing adhesive properties, thereby providing optimal web handling capabilities. The rolls are easy to replace and offer optimal accessibility for cleaning and maintenance.

Maintains optimal adhesion with uniform pressure from the silicone roll across the width

Adopts cooling rolls with excellent cooling effects

Easy replacement of cooling rolls

Equipped with Teflon tape device

3 Rolls Press Type

Cooling Roll

Silicone Pressing Roll

Steel Supporting Roll

Cooling Roll / Silicone Roll / Back-up Roll

Up To Ø 800mm

Up To Ø 260 mm

Up To Ø 210 mm

Quick Change Equipment For 3 Rollers

The lamination configuration of a 3-rolls system, which applies cooling and pressure, is the most critical system in the machine. With highly precise engineering, the rolls ensure consistent temperature and pressure across the entire web, preventing stress on the coated materials and enhancing adhesive properties, thereby providing optimal web handling capabilities. The rolls are easy to replace and offer optimal accessibility for cleaning and maintenance.

Winder

Dancer roll type Precise Tension Control

Air shaft/ Shaftless chucking for quick change

Linear movement type Auto splicer for unwinder

Near roll : automatically keep the gap between the winding web roll

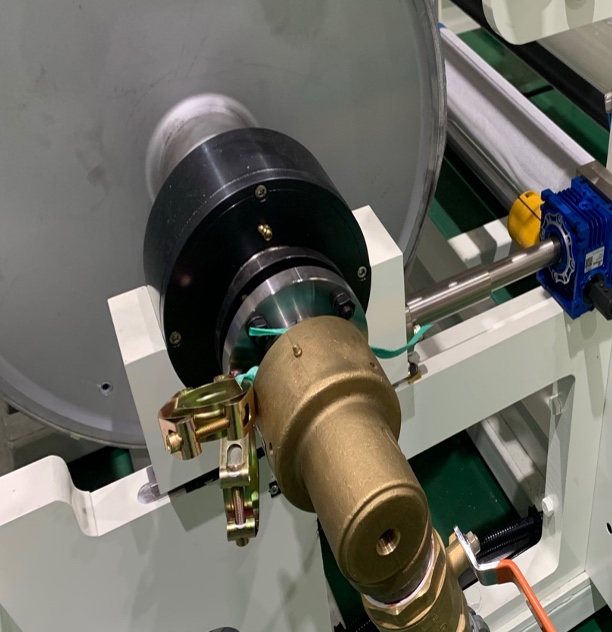

Primer Coating

Gravure coating unit with integrated enclosed doctor blade

Fast change of doctor blade

Sleeve-type pressure roller for rapid job transitions

Easy access to the detachable nozzles and internal rollers by wide opening space

Customized Layout / Option

Flexible component-based design for customized cost effective user layouts

User-friendly modular configuration system

Thickness Measurement, Corona Treatment, Quality Inspection, Energy-saving And More